Excellence in Operability and Economy

KAMOME Controllable Pitch Propellers were created in 1961, featuring proprietary technology. For nearly half a century we have sustained a commitment to research and technical development so that we can satisfy customer needs. Propellers are installed in ships of a broad range of sizes: from small boats to 16,000kW ships, and in merchant ships, fishing ships, ferries, research ships and maritime development platforms. With cumulative delivery of more than 5,400 units, we have the world’s leading manufacturing technologies and market sales share.

Superiority in Ship Control

KAMOME Controllable Pitch Propellers produce all speeds necessary for full-speed sailing, low-speed sailing, and stop and backward sailing by controlling propeller pitch. Without changing engine revolutions they enable ships to stop quickly in a short distance after controlling the propeller pitch. This enhances ship control and safety in urgent situations.

Energy Saving

Output required for propulsion changes constantly in line with external factors and sailing conditions, such as operation schedules and cargo, in addition to sea conditions such as wind direction and tides. Optimal control of the propeller pitch according to the ship load easily leads to energy conservation by capitalizing on the engine’s properties.

Environmentally Friendly Propulsion Systems

With a controllable pitch propeller, the main engine can be operated at constant revolution irrespective of the ship’s sailing speed. It helps construct a drive system in which a power generator and hydraulic equipment are driven by a fuel-efficient main engine. This eliminates the need for operating an auxiliary engine and reduces fuel consumption as well as CO2 and nitrogen oxide (NOx) emissions from the engines.

Features

- Excellent operability and construction supported by our up-to-date research and extensive experience

- Controllable pitch propellers are durable and thoughtfully designed for easy assembly and maintenance

- Original control system places ship operation efficiency as a top-priority

- Wide array of models and control systems suit different conditions for installation in numerous types of ships

- Continuous review of propeller efficiency and vibration and noise control guarantee safe and comfortable sailing

Product List

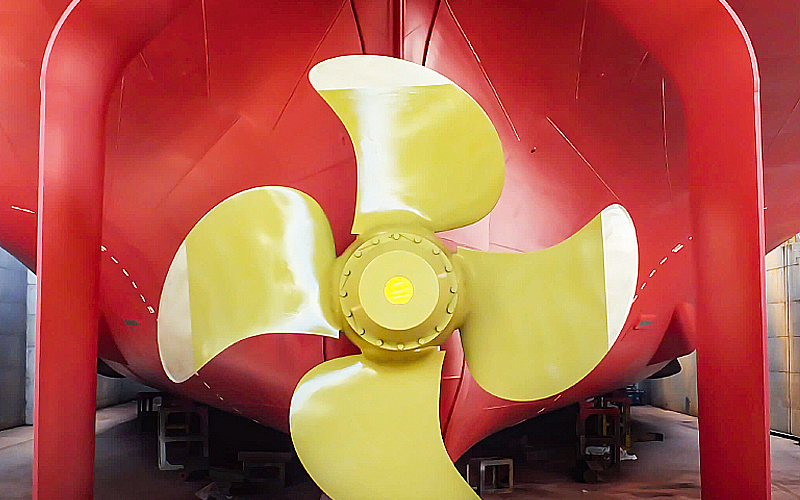

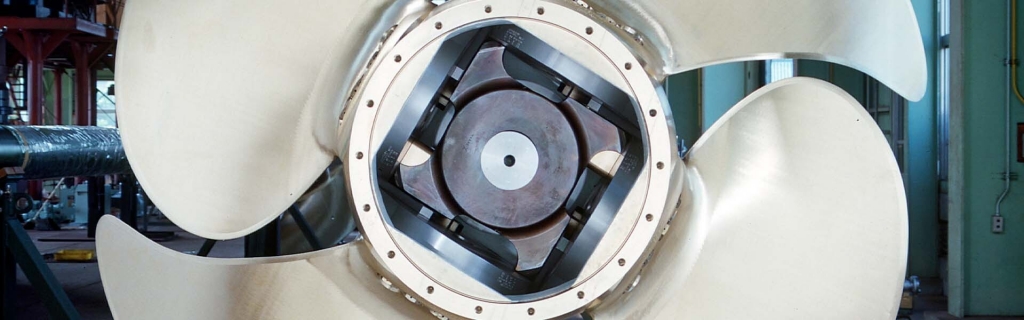

KAMOME Controllable Pitch Propellers: A-type Series

A-type series propellers are mainly for small- and medium-sized ships. The split-type propeller hub consists of fore and aft sections. Blades are assembled in between hubs and easy to overhaul and reassemble.

Models with built-in reduction gears—CPR-AV type, CPR-AH type (different axis types) and CPC-AR type (same axis type)—are available in addition to the standard CPC-AF type.

Standard Dimension

| Type | A | B | C | D((Round number)) | E(Minimum) | F | G | H |

|---|---|---|---|---|---|---|---|---|

| CPC-36N | 860 | 332 | 528 | 220 | 310 | 310 | 570 | 338 |

| CPC-38AN | 1055 | 420 | 635 | 255 | 370 | 370 | 633 | 373 |

| CPC-45AN | 1130 | 445 | 685 | 320 | 420 | 420 | 713 | 433 |

| CPC-53AF | 1105 | 382.5 | 722.5 | 340 | 400 | 500 | 880 | 510 |

| CPC-65AF | 1255 | 410 | 845 | 420 | 430 | 560 | 840 | 420 |

| CPC-80AF | 1510 | 515 | 995 | 500 | 490 | 610 | 970 | 480 |

Particular of Mover

| Type | Main pump Discharge capacity (L/min) | Main pump Electric motor kW×φ | Stand-by pump Discharge capacity (L/min) | Stand-by pump Electric motor kW×φ | Cooler heat transfer area m² | Sub-tank capacity L | Difference between core and tank top axis mm(Minimum) |

|---|---|---|---|---|---|---|---|

| CPC-36N | 14 | 2.2×6 | 10 | 0.4×4 | 0.4 | 90 | * |

| CPC-38AN | 15 | 2.2×6 | 10 | 0.4×4 | 0.4 | 90 | * |

| CPC-45AN | 26 | 3.7×4 | 10 | 0.4×4 | 0.7 | 90 | * |

| CPC-53AF | 28 | 5.5×4 | 14 | 2.2×6 | 0.7 | 200 | 430 |

| CPC-65AF | 28 | 5.5×4 | 14 | 2.2×6 | 0.7 | 200 | 450 |

| CPC-80AF | 38 | 7.5×4 | 20 | 3.7×4 | 1.3 | 200 | 520 |

Related links

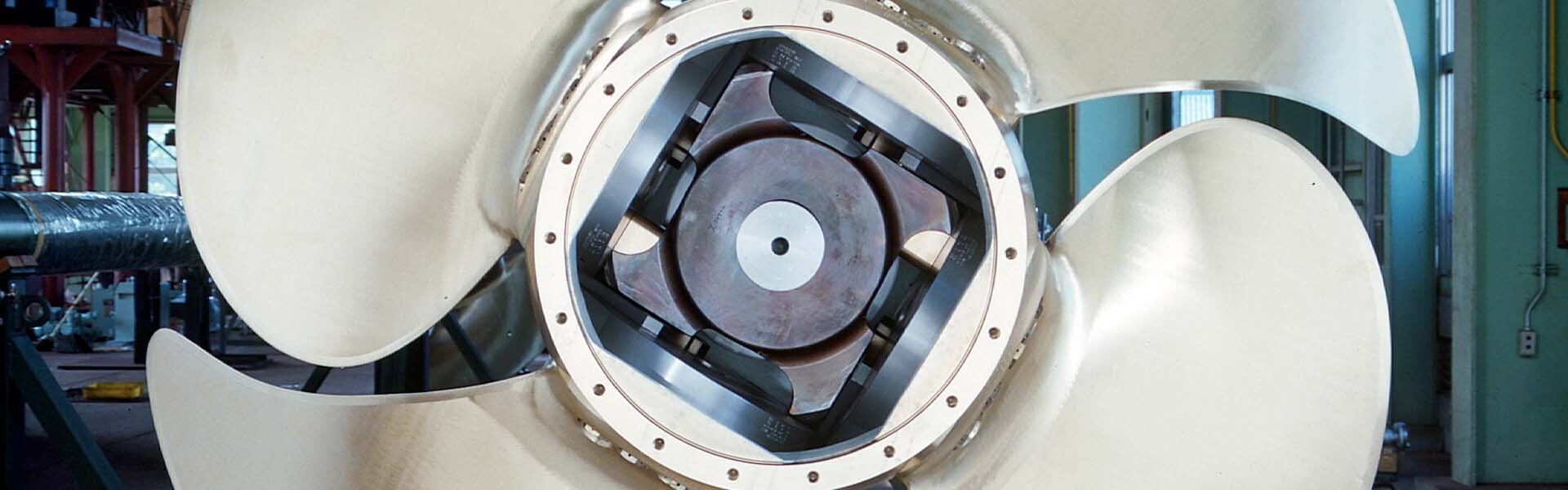

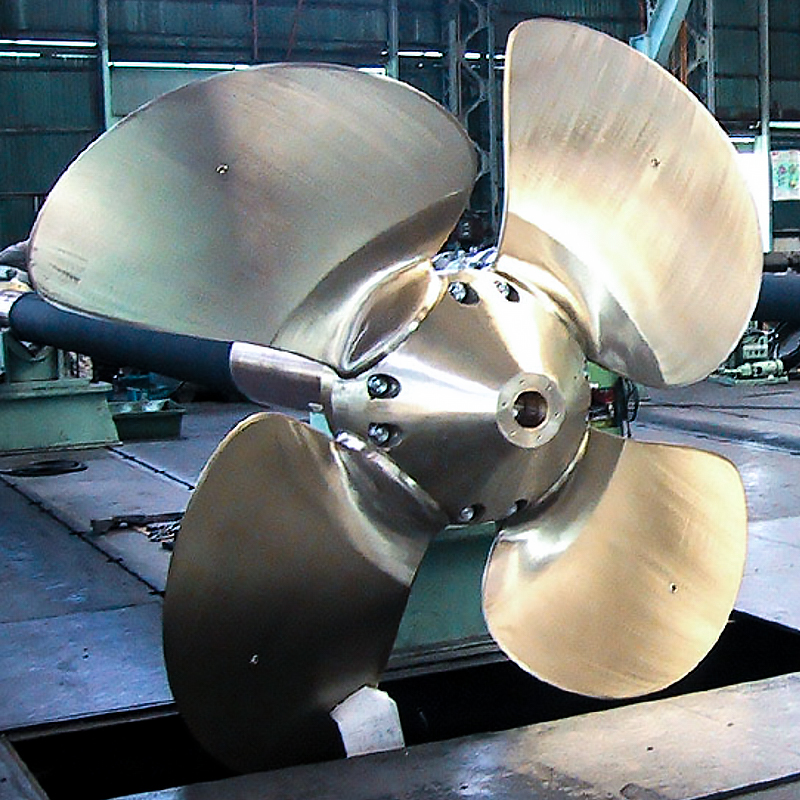

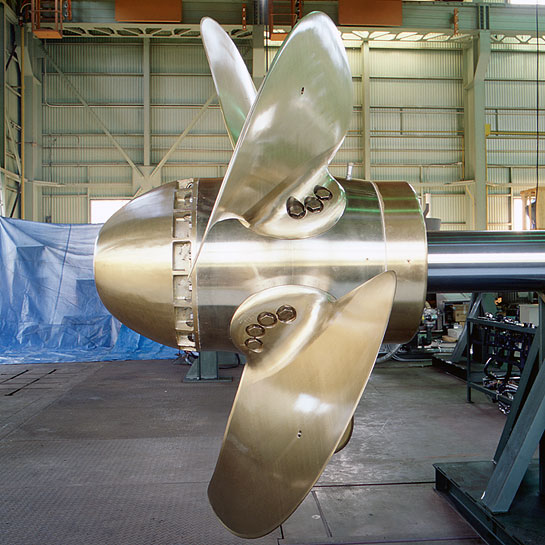

KAMOME Controllable Pitch Propellers: B-type Series

B-type series propellers are chiefly for medium- and large-sized ships. They feature a solid-type propeller hub. Propeller blades are individually assembled.

Models with built-in reduction gears—CPR-BV type, CPR-BH type (different axis types) and CPC-BR type (same axis type)—are available in addition to the standard CPC-BF type.

Standard Dimension

| Type | A | B | C | C’ | D(Round number) | E(Minimum) | F | G | H |

|---|---|---|---|---|---|---|---|---|---|

| CPC-90B/95F | 1695 | 547.5 | 1147.5 | 0 | 580 | 550 | 700 | 1120 | 530 |

| CPC-95BF | 1695 | 547.5 | 1147.5 | 0 | 580 | 550 | 700 | 1170 | 560 |

| CPC-100B/110F | 1850 | 570 | 1280 | 0 | 640 | 580 | 840 | 1250 | 575 |

| CPC-110BF | 1105 | 382.5 | 722.5 | 0 | 340 | 400 | 500 | 880 | 510 |

| CPC-110B/115F | 2015 | 617.5 | 1397.5 | 0 | 640 | 620 | 880 | 1402 | 662 |

| CPC-120BF | 2950 | 745 | 1460 | 745 | 730 | 675 | 920 | 1435 | 665 |

| CPC-130BF | 3140 | 832.5 | 1504.5 | 803 | 780 | 790 | 970 | 1610 | 700 |

| CPC-140BF | 3380 | 882.5 | 1627 | 870.5 | 850 | 880 | 1090 | 1650 | 790 |

| CPC-150BF | 3725 | 1000 | 1772 | 953 | 1020 | 735 | 1185 | 2000 | 865 |

| CPC-160BF | 4090 | 1090 | 1909 | 1091 | 1020 | 880 | 1380 | 1925 | 925 |

| CPC-170BF | 4260 | 1247.5 | 1865 | 1147.5 | 1200 | 1200 | 1400 | 2060 | 980 |

Particular of Mover

| Type | Main pump Discharge capacity (L/min) | Main pump Electric motor kW×φ | Stand-by pump Discharge capacity (L/min) | Stand-by pump Electric motor kW×φ | Cooler heat transfer area m² | Sub-tank capacity L | Difference between core and tank top axis mm(最小) |

|---|---|---|---|---|---|---|---|

| CPC-90B/95F | 70 | 11×4 | 28 | 5.5×4 | 1.3 | 300 | 540 |

| CPC-95BF | 70 | 11×4 | 28 | 5.5×4 | 1.3 | 300 | 550 |

| CPC-100B/110F | 85 | 15×4 | 38 | 7.5×4 | 1.7 | 300 | 550 |

| CPC-110BF | 85 | 15×4 | 38 | 7.5×4 | 1.7 | 300 | 550 |

| CPC-110B/115F | 85 | 15×4 | 38 | 7.5×4 | 1.7 | 300 | 600 |

| CPC-120BF | 85 | 15×4 | 85 | 15×4 | 1.7 | 500 | 700 |

| CPC-130BF | 85 | 15×4 | 85 | 15×4 | 1.7 | 500 | 700 |

| CPC-140BF | 85 | 15×4 | 85 | 15×4 | 1.7 | 500 | 700 |

| CPC-150BF | 137 | 22×4 | 137 | 22×4 | 2.8 | 600 | 750 |

| CPC-160BF | 140 | 30×4 | 140 | 30×4 | 2.8 | 600 | 800 |

| CPC-170BF | 175 | 37×4 | 175 | 37×4 | 3.5 | 800 | 800 |

Related links

Feathering Propellers

Feathering propellers acquired their name because of their similarity to a bird with its wings furled. They have a maximized propeller pitch and a blade surface nearly parallel to the water flow to minimize resistance when they are not in operation. Their properties are shown in sailing ships and double-ender ferries.

Related links

Control System

As a one-stop manufacturer of propulsion and ship operation systems, we engage in integrated production of controllable pitch propellers, side thrusters and rudders to offer systems that satisfy energy conservation and safe operation needs.

Optimum Propulsion Control System – PRO-CON CX-300

CX-300 remotely controls the pitch of a controllable pitch propeller and the revolution speed of the main engine (governor). With ALC, ASC, PGM, OLP, combinator, load setting, pitch limit trimming, automatic reduction, automatic pitch neutralization and other functions, it makes it easy for users to perform optimal control of the main engine and controllable pitch propeller. This helps suppress load fluctuations on the main engine and saves energy.

Joystick Control System – MACS-KM

MACS-KM unifies the individual operations of a controllable pitch propeller, bow thruster, and high performance rudder into a single joystick and steering dial. The Optimum Control Program embedded in the computer allows the ship to not only be moved forward and backward, but moved laterally and diagonally, and turned simply.

This dramatic improvement in ship control facilitates berthing and unberthing control and prevents accidents. Easy operations for optimal ship control reduce fluctuations of load on the main engine and save energy.

Related links